I have had an issue with my elevator trim wheel for quite a long time now where the gears go out of alignment and it needs to be constantly readjusted. This was a major irritation as it was not a simple process. The actual gear realignment was easy, but in order to access them, I had to unbolt my yoke column and move it out of the way. Then unbolt the throttle quadrant pedestal base and move it back to be able to access the rotary controller and the gears inside.

In order for the shaft of the trim wheel, which is a 3/8 inch carriage bolt, the 3/8 inch hole that is drilled into the throttle quadrant pedestal base has to be made slightly larger so that it can spin freely and not end up acting as a nut by threading the hole when it is inserted. I used a nylock nut on each side of the pedestal wall tightened just to the point of letting the shaft spin without tightening.

Although good in theory, the problem with this design is that because the nuts on each side of the pedestal wall are not completely tightened the shaft does not spin true. Over time the hole gets slightly larger from wear, and the shaft wobbles around causing the gears to come out of alignment and either bind or sometimes just turn off each other and not make contact.

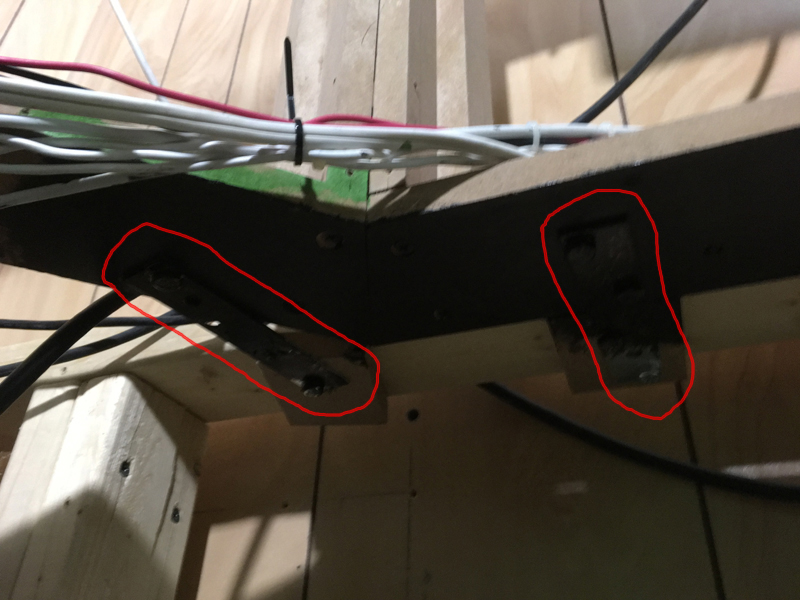

This is what the old gear design looked like:

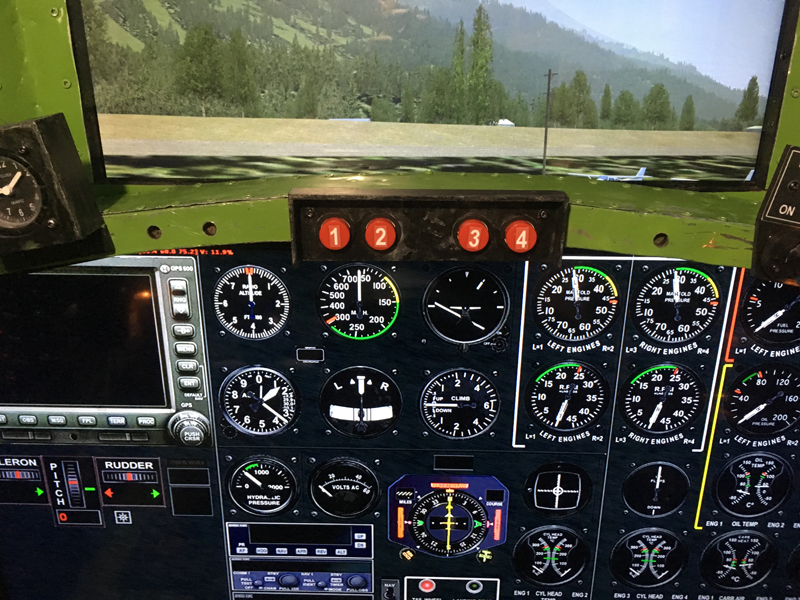

The main reason for using gears with potentiometers is to act as a step down. That is to reduce the rotation amount. For example I use them with my throttle levers. The travel the throttle lever goes through is much less than what the travel the potentiometers goes through so you use gears to accomplish this.

I am using Rotary Controllers and not potentiometers for the trim functions. A rotary controller just turns infinitely forward or backward not coming to a stop and not having a definitive travel length like a potentiometer has. Therefore gears are not needed with a rotary controller. It can just be connected directly to the shaft of the elevator trim wheel. I actually did this with my aileron trim wheel when I moved it from the throttle quadrant pedestal base to my icing controls box on the left side flight deck and didn`t realize at the time that this could work for my elevator and rudder trim wheels as well. In fact I didn`t realize it until after I completed the mod and began to write up this post that I had used this principle before.

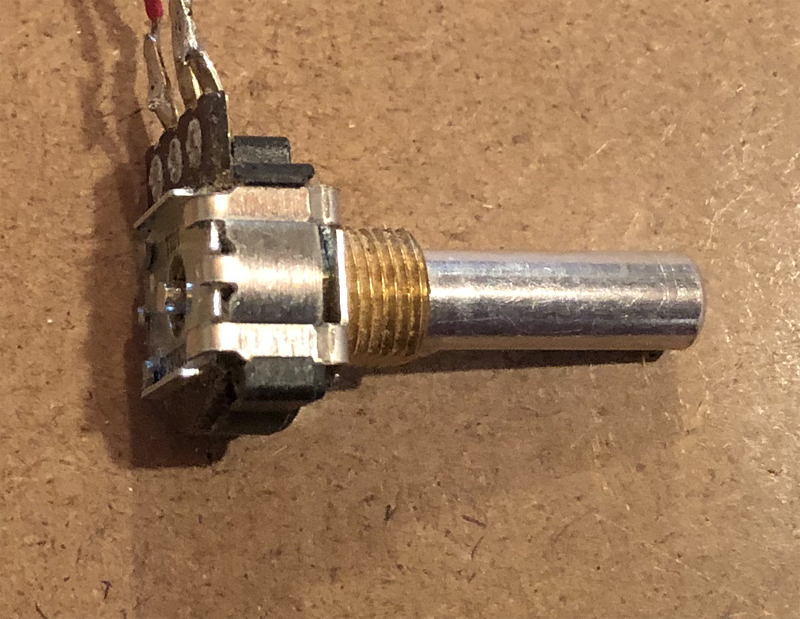

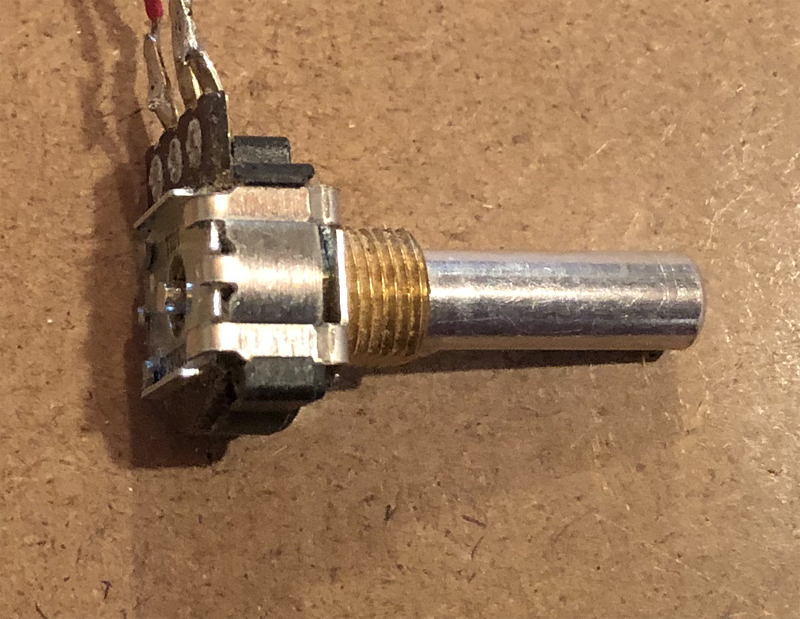

This is what a rotary controller looks like. Note that it just has a 1/4 inch smooth solid shaft with no knurling or split slots that you can use to attach it to something easily. It is too bad that it wasn`t threaded because they make a 3/8 inch to 1/4 inch metal coupler that I could have used to connect the rotary controller to the elevator trim shaft.

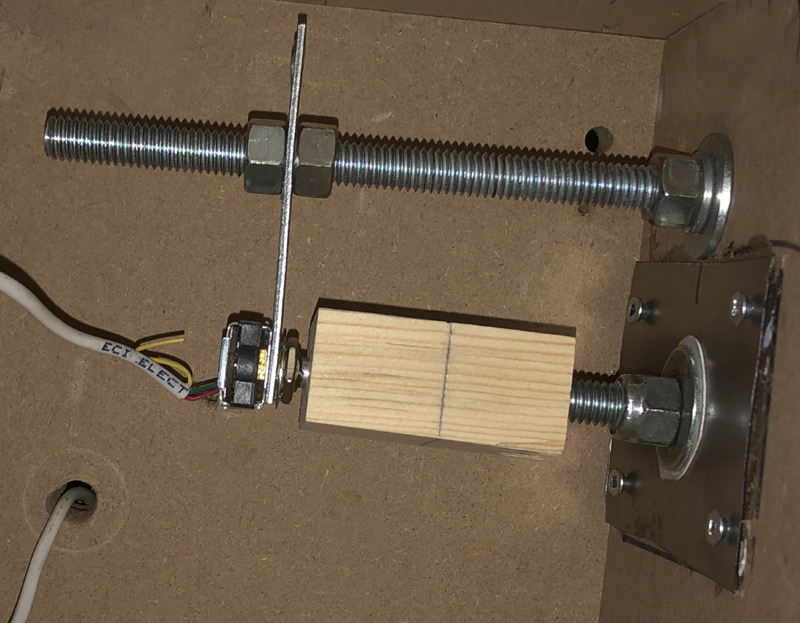

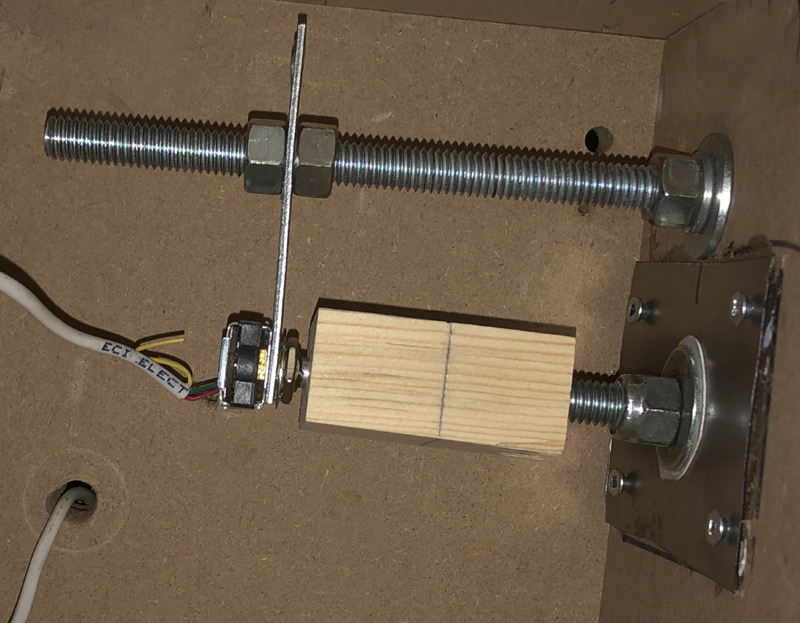

I decided to make a coupler out of wood and drill a 1/4 inch hole for the rotary controller in one end and a 23/64 inch hole drilled in the other end. I then inserted a 3/8 inch bolt into the 23/64 inch hole making it threaded.

I made steel plates to put over the holes on each side of the base. This helps keep the shaft from wobbling and makes a smooth surface for the nyloc nuts to spin on. I put homemade plastic washers cut from a margarine container and large steel washers on each side of the hole as well. Then I put the elevator trim wheel shaft through the hole in the base and put the inside nyloc nut on. This nut can be tightened to allow for some friction so the wheel doesn`t turn too easily with no resistance.

Then I screwed the threaded end of the wood coupler onto the 3/8 inch carriage bolt of the elevator trim wheel turning it slightly farther than the threads for a snug fit. Then pushed the shaft of the rotary controller into the 1/4 inch hole. The shaft is just mere microns larger than 1/4 inch so when you push it on it is a snug fit. I just left the mending plate on the rotary controller and attached it to the top bolt in the same fashion as with the gear system I had. This is still needed to keep the rotary controller body from spinning instead of just the shaft. It also acts as a support so the shaft should not wobble.

I have had this in place for about a week now and it is working well. There is virtually no friction on the coupler itself, so I don`t foresee it loosening at all.

Bill